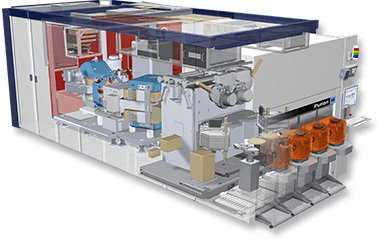

Purion H ion implanters bring the industry-leading process control of our medium current platforms to the full range of demanding, high-current applications. The flexibility of the platform enables us to tailor Purion H to the specific energy or dosing requirements of your application. The Purion H offers unmatched versatility, throughput and uniformity, so you can achieve greater yield with the lowest cost of ownership.

Purity

Unique scanned-spot-beam architecture with the Purion Contamination Shield™. The Purion High Current Platform features a five-filter beamline design including a field proven energy filter for extreme purity. Each system includes the patented, filament-free microwave Plasma Electron Flood (PEF) to enable wafer neutralization without additional metals contamination.

Precision

Purion Vector™ dose and angle control system ensures highly precise, uniform dopant placement across the entire wafer by precise measurement and control of both horizontal and vertical angles. The scanned spot beam architecture enables a unique damage engineering knob to tailor the implant profile to optimize device performance.

Productivity

IdealScan™ is an Axcelis patented technique to scan the spot beam to maximize the use of the spot beam for highest beam current in the region of interest. The combination of high beam current and the Purion 500 wph end station makes Purion High Current tools the highest in productivity.

Microwave PEF Technology

Microwave PEF Technology